Ibhulogi

Enqubweni yokugaya, izigayo zokugcina zingahlukaniswa zibe izinhlobo ezimbili: ukugaya phansi kanye nokugaya phezulu, ngokuvumelana nobudlelwane phakathi kwesiqondiso sokuzungeza kwesisiki sokugaya kanye nesiqondiso sokusika ukudla. Lapho isiqondiso sokuzungezisa se-milling cutter sifana nesiqondiso sokuphakela kwe-workpiece, kubizwa ngokuthi i-click milling. Isiqondiso sokujikeleza komsiki wokugaya siphambene nomsebenzi

2024-01-04

Izimbangela Nezixazululo Zezimpawu Zokudlidliza Kunqubo Yokugaya

2024-01-04

Unqenqema lwethuluzi ngemva kokulola isondo lokugaya elivamile noma isondo lokugaya idayimane linezikhala ezincane (okungukuthi, ukusika nokusaha) amadigri ahlukene. Phakathi nenqubo yokusika, i-notch microscopic yonqenqema lwamathuluzi kulula ukunwetshwa, okusheshisa ukugqoka nokulimala kwamathuluzi. Imishini yesimanje enesivinini esikhulu kanye namathuluzi omshini ozishintshayo abeka phambili i-requi ephezulu

2024-01-04

I-alloy milling cutter okwamanje ingelinye lamathuluzi athuthukile e-China. I-alloy milling cutter iyithuluzi lokusika elivame ukusetshenziswa kakhulu lokucubungula umkhiqizo wezinkuni. Izinga le-carbide milling cutter lihlobene eduze nekhwalithi yemikhiqizo ecutshunguliwe. Ukukhetha okulungile nokunengqondo kwabasiki be-carbide milling kubaluleke kakhulu ekuthuthukiseni ikhwalithi yomkhiqizo, ukunciphisa umjikelezo wokucubungula

2024-01-04

Ukukhetha okulungile kwe-milling cutter:Ukuze ukhethe i-milling cutter eyongayo futhi ephumelelayo, i-milling cutter efanele kakhulu kufanele ikhethwe ngokuvumelana nokuma kwempahla okufanele isikwe, ukunemba komshini, njll. Ngakho-ke, izici ezibalulekile ezifana nobubanzi bomshini wokusika, inombolo emaphethelweni, ubude bonqenqema, i-engeli ye-helix, nezinto ezibonakalayo kufanele kucatshangelwe

2024-01-04

Phakathi nenqubo yokugaya, i-milling cutter ngokwayo izogqokwa futhi ibe buthuntu ngenkathi isika ama-chips. Ngemva kokuba i-milling cutter ibuthuntu ngokwezinga elithile, uma iqhubeka nokusetshenziswa, izoholela ekwandeni okukhulu kwamandla okugaya kanye nezinga lokushisa lokusika, futhi inani eligugayo le-milling cutter nalo lizokhula ngokushesha, ngaleyo ndlela lithinte umshini. ukunemba kanye nekhwalithi ephezulu kanye ne

2024-01-04

Izinyathelo zokuphepha zokusebenzisa kahle izigayo zokugcina

2024-01-04

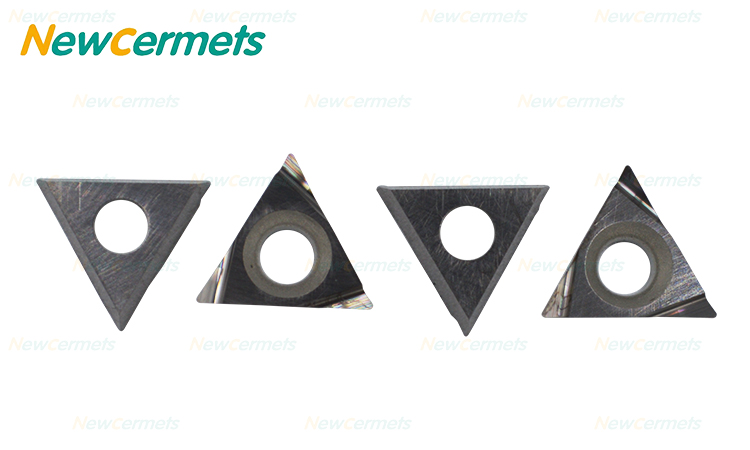

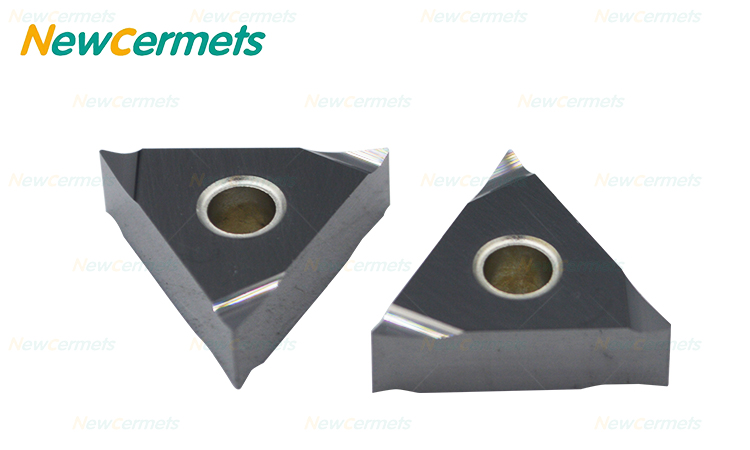

Ama-blades ama-cermet cutters abukhali, futhi ukumelana nokugqokwa kuphakeme izikhathi eziningi kunemimese yensimbi, okungashiwo ukuthi ayigugi. Nakuba izinga lokuthuthukiswa kwemimese ye-ceramic yaseShayina lingelibi, ukuthuthukiswa kokusetshenziswa okusebenzayo kuhamba kancane kakhulu. Ngakho yiziphi izici zemimese ye-cermet? Inale mehluko! Ake sibheke!

2024-01-04

Yiziphi izici okufanele zinakwe ekugcinweni kwansuku zonke kwekhanda lokusika?

2024-01-04

Isingeniso sokusetshenziswa okufanele kwama-ceramic bladesI-Ceramic ithuluzi elinokuqina okuphezulu ngemuva kwensimbi enesivinini esikhulu, i-carbide enosimende, namathuluzi e-carbide anosimende; kanjani ukusebenzisa izindwani Ceramic ngendlela efanele?

2024-01-04