Blog

In the milling process, end mills can be divided into two types: down milling and up milling, according to the relationship between the rotation direction of the milling cutter and the cutting feed direction. When the rotation direction of the milling cutter is the same as the workpiece feed direction, it is called climb milling. The rotation direction of the milling cutter is opposite to the work

2024-01-04

Causes and Solutions of Vibration Marks in Milling Process

2024-01-04

The cutting edge of the tool after being sharpened by an ordinary grinding wheel or a diamond grinding wheel does have microscopic gaps (ie, micro chipping and sawing) of different degrees. During the cutting process, the microscopic notch of the tool edge is easy to expand, which accelerates the tool wear and damage. Modern high-speed machining and automated machine tools put forward higher requi

2024-01-04

Alloy milling cutter is currently one of the advanced tools in China. Alloy milling cutter is the most commonly used cutting tool for wood product processing. The quality of carbide milling cutter is closely related to the quality of processed products. The correct and reasonable selection of carbide milling cutters is of great significance for improving product quality, shortening processing cycl

2024-01-04

The right choice of milling cutter:

In order to choose an economical and efficient milling cutter, the most appropriate milling cutter should be selected according to the shape of the material to be cut, machining accuracy, etc. Therefore, important factors such as the diameter of the milling cutter, the number of edges, the length of the edge, the helix angle, and the material must be consider

2024-01-04

During the milling process, the milling cutter itself will be worn and dull while cutting chips. After the milling cutter is blunt to a certain extent, if it continues to be used, it will lead to a significant increase in the milling force and cutting temperature, and the wear amount of the milling cutter will also increase rapidly, thus affecting the machining accuracy and surface quality and the

2024-01-04

Precautions for the correct use of end mills

2024-01-04

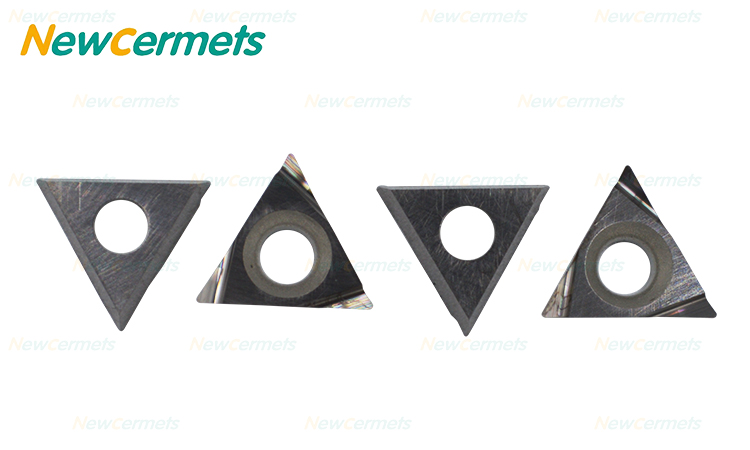

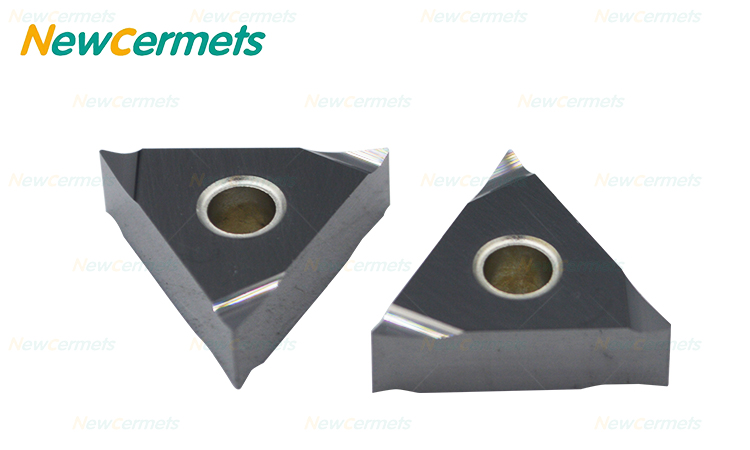

The blades of cermet cutters are sharp, and the wear resistance is dozens of times higher than that of steel knives, which can be said to never wear out. Although the development level of Chinese ceramic knives is not bad, the development of practical application is very slow. So what are the characteristics of cermet knives? It has these differences! Lets come look!

2024-01-04

What aspects must be paid attention to in the daily maintenance of the cutting head?

2024-01-04

Introduction to the correct use of ceramic blades

Ceramic is a high-hardness tool material after high-speed steel, cemented carbide, and coated cemented carbide tools; how to use ceramic blades correctly?

2024-01-04